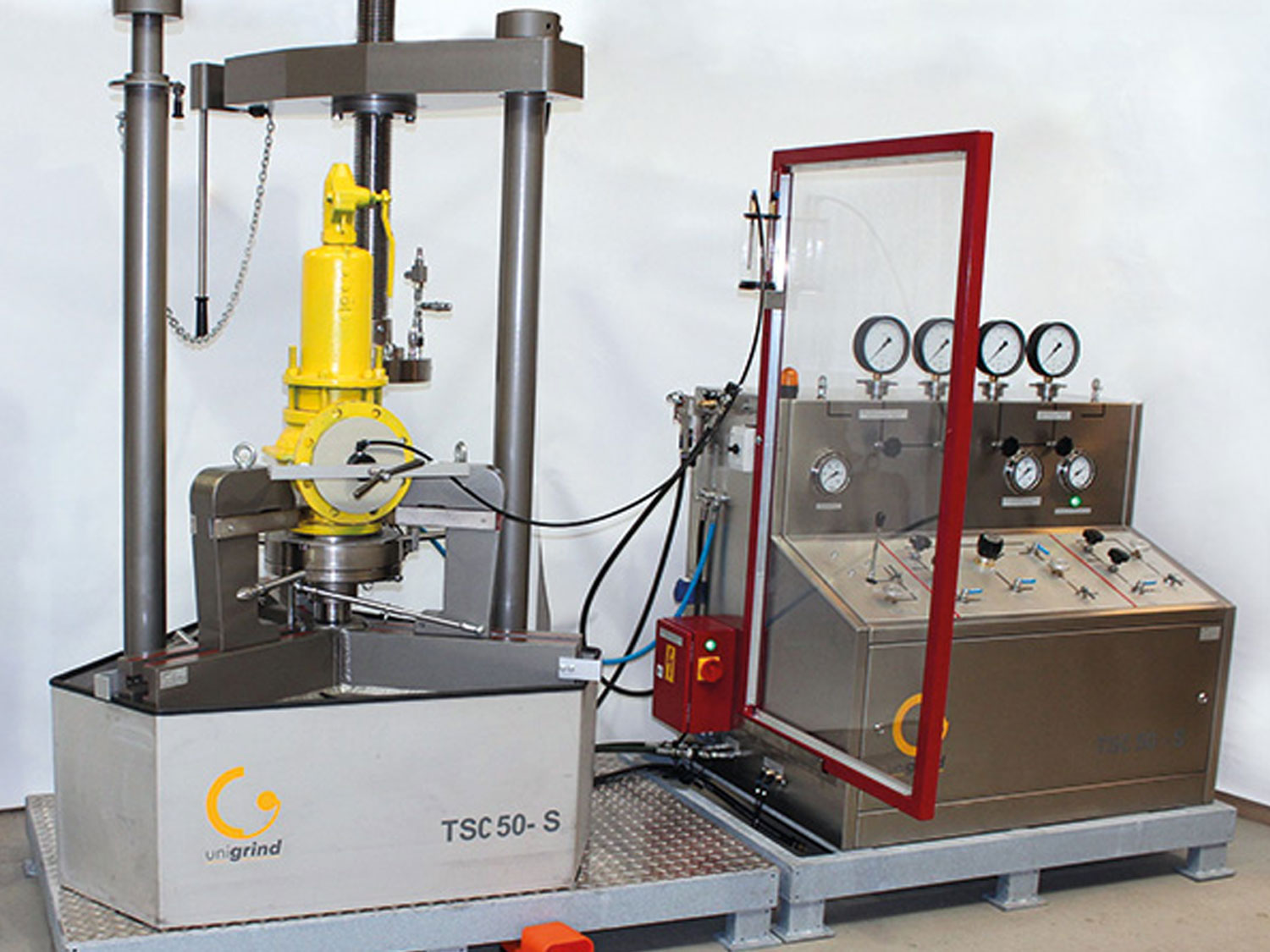

Pressure Safety Valve Calibration

Pressure Safety valves are essential for managing pressure within pressurized systems, such as pipelines, equipment and pressure vessels, to prevent blow-out and ensure efficient operation. Pressure safety valves need regular calibration to guarantee they open at the correct pressure levels. Calibration helps prevent overpressure situations, maintains system efficiency, and avoids unexpected downtimes and

costly repairs. Signs that your valve needs calibration include inaccurate pressure release. The primary advantage of pressure calibration is the assurance of measurement accuracy. Over time, pressure sensors and gauges can drift due to factors like environmental conditions, mechanical stress, and normal wear and tear. PSV calibration is done by comparing the set pressure, which is the rapid released action popping of the PSV, to the displayed value of the reference standard.

Quality Setup. Honest Service.

Great Value

Our professional team works to increase productivity and cost effectiveness on the market

Completed Projects

0

Satisfied Clients

0

Ongoing Projects

0

Customer relations with transparent communication..

Business solutions can help you get there.